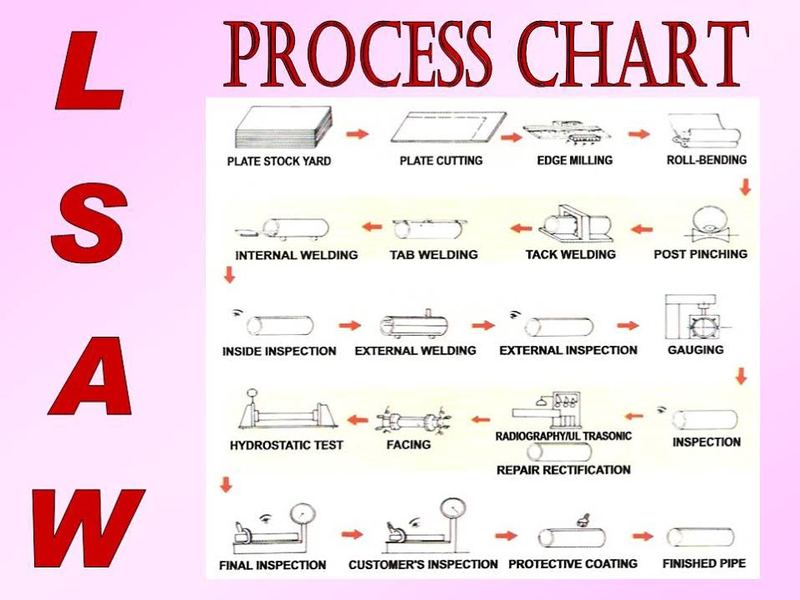

High quality plates are procured from well –known local manufactures like Steel Authority of India, Essar Steel , Tata Steel, or are imported from leading steel mills abroad. Thereafter, physical and chemical properties are checked in the laboratory and verified with the test certificates. These plates are accurately cut to the required dimension, edges are prepared as per manufacturing codes, and then fed into the rolling machine.

The plates are rolled in the rolling machine into cylindrical shape of lengths varying from 4-12 mtrs. After post pinch operation, the pipes are subjected to fit up & Tack welding by Mig Process for onward root run by MIG Process to provide back up for SAW. Thereafter, the longitudinal seam is submerged arc welded both from outside and inside, to form a strong weld joint followed by set Parameters of current & Voltage and monitored closely to ensure quality by the QA/QC Engineer.

The pipes are then moved to gauging station to achieve perfect roundness with a Hydraulically operated Press (Machine) to achieve the Perfect Profile. The pipe ends are beveled wherever required by the customer .Each pipe is subjected to strict quality control.

The pipes also undergo ultrasonic testing apart from radiography and hydrostatic testing as per the relevant codes and specifications to which the pipes are manufactured. Each pipe bears Sr.No., Specification, Size, Heat Number etc. for traceability as and when required.