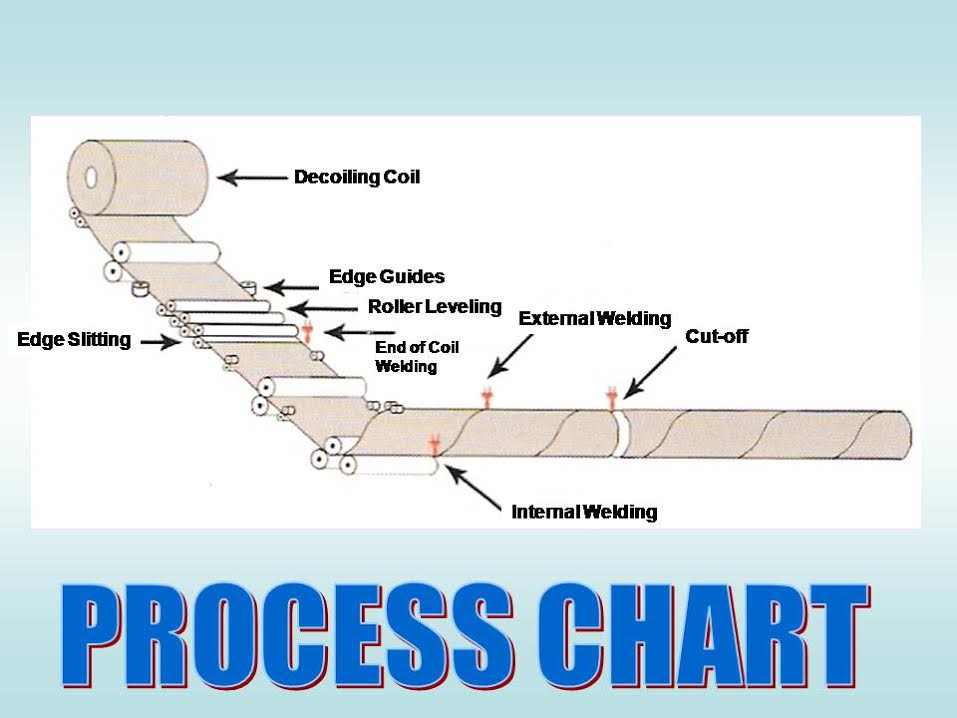

Helical Submerged Arc Welded Pipes or commonly called Spiral Pipes are made from hot rolled coils. The Spiral Pipe forming Mill. The Pipe Mill decoils the strip, straightens it, prepares the edges for welding and feeds it into forming station to form the coil into pipe with remote Control Pannel by the operator. The pipe is then Rolled on to the platform for visual inspection.

The pipe is then welded internally and externally using the most advanced Submerged Arc Welded Technology. Once formed and welded the pipe is cut to the required length, all operations being carried out simultaneously without halting the production process. The pipe then rolls onto the bench for visual inspection. The Edge beveling radiography, Ultrasonic testing, Hydrostatic Testing is carried out as per the relevant codes and the specifications to which the pipes are manufactured. The manufacturing process is useful & economical since the pipes in different diameters range can be formed using the same width of basic Raw Material (H.R.Coils) by Setting the forming angle from 10 Degree to 45 degree i.e. smaller the Angle, Larger the diameter of pipe and vise versa.