Financial Year 2016-17

Quarter Ended 30-06-2016

Quarter Ended 30-09-2016

Quarter Ended 31-12-2016

Quarter Ended 31-03-2017

Financial Year 2017-18

Quarter Ended 30-06-2017

Quarter Ended 30-09-2017

Quarter Ended 31-12-2017

Quarter Ended 31-03-2018

Financial Year 2018-19

Quarter Ended 30-06-2018

Quarter Ended 30-09-2018

Quarter Ended 31-12-2018

Quarter Ended 31-03-2019

Financial Year 2019-20

Quarter Ended 30-06-2019

Quarter Ended 30-09-2019

Quarter Ended 31-12-2019

Quarter Ended 31-03-2020

Financial Year 2020-21

Quarter Ended 30-06-2020

Quarter Ended 30-09-2020

Quarter Ended 31-12-2020

Quarter Ended 31-03-2021

Financial Year 2021-22

Quarter Ended 30-06-2021

Quarter Ended 30-09-2021

Quarter Ended 31-12-2021

Quarter Ended 31-03-2022

Financial Year 2022-23

Quarter Ended 30-06-2022

Quarter Ended 30-09-2022

Quarter Ended 31-12-2022

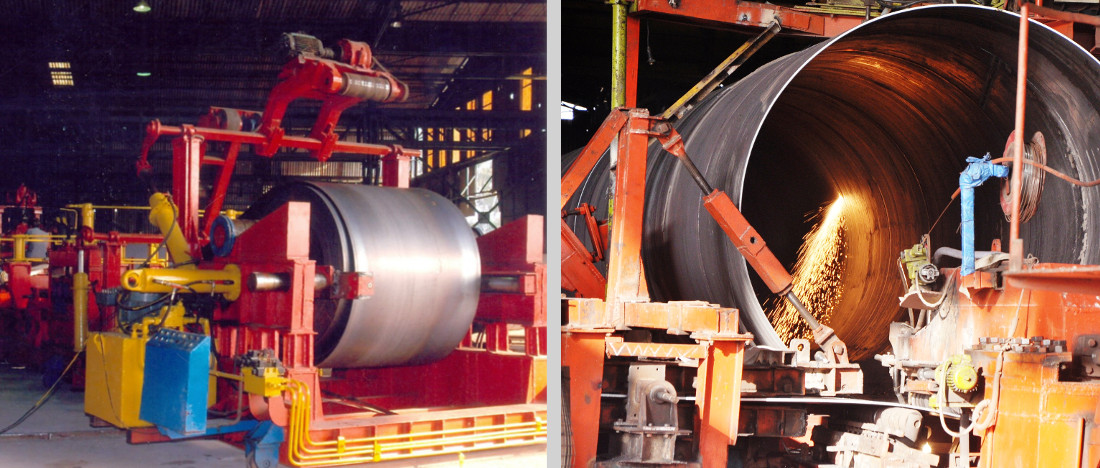

Quality checks are conducted at stages during the process of manufacturing right from the Raw Material to the finished product.Samples from incoming Raw Material is drawn and tested in the Lab setup In-house to ensure its mechanical properties, chemical composition in accordance with the requirements/relevant Specifications and comparability with the Mill Test Certificates furnished by the Steel Manufacturers before taking into production planning.

Dimensional/Visual Inspection is carried out during the Process of Sizing, Edge Preparation/Beveling, Pipe forming,, Pre & Post Submerged Arc Welding Operations, Profiling, Finishing, Hydro Testing and Final Inspection before dispatch. All documents comprising of Test Reports prepared at various stages under witness by the Inspecting Authority are summarized in "Work Test Certificate" issued under the Seal of the Company duly signed by the Quality Control Manager.

TESTING FACILITIES

1. Hydro Testing (Test Pressure)

Each and every pipe in the range of 12 inches to 100 inches in varied length from 4 Mtrs to 12 Mtrs filled with water is tested upto a pressure of 51 KG/CM2 in accordance with IS 3589-2001 on the Hydrotesting unit installed inhouse at Mukat Pipes Limited.

2. UNIVERSAL TESTING MACHINE

All Tensile Tests and Guided Bend Test are conducted as per IS Codes on the UTN-40 Machine installed inhouse at Mukat Pipes Limited.

3. NON DESTRUCTIVE TESTS

All tests like Radiography, Ultrasonic, Dye Penetrant are also carried out as per specifications and requirements of the customers.

SOURCE AND STANDARDS

Sources of Raw Material (ISI MARK).

- Steel Authority of India.

- TATA Steel

- ESSAR Steel

- Jindal Steel

STANDARDS OF CONSUMABLES (AWS/SFA.A.517) -

- Automelt Copper Coated Wire Gr-A (EL-8),

- Corresponding Flux Automelt Gr.-II.

Page 5 of 8